Company news

Installation and connection of multistage pump

Installation and connection of multistage pump

1, Handing

1, Handing

When lifting the entire pump with motor, follow these instructions:

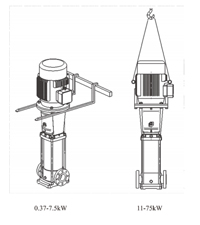

(1), Pump with motor sizes 0.37-7.5kW:

Lift the pump in the motor flange by means of straps or the like.

(2). Pump with motor sizes 11-75kW:

Lift the pump by means of the motor eyebolts.

2, Pump installation

Pump size and dimension pls contact sales supply.

The pump should be sited in a well ventilated and frost-free position.

The distance between pump-motor by fan with enough air.

To reduce the head loss of inlet as least as possible, the inlet pipe shall be as short as possible.

Ensure the check valve is installed in pipe line system before the pump installation. If pump is used for boiler water supply, a check valve must be installed in the piping between pump and boiler.

Pump shall be installed in cement base or other similar base with suitable height. It can also be installed in fixed grounds or fixed brackets on wall. Pay attention not to let the weight of pipe system on pump to prevent pump from damage.

Caution: When installation, motor is not allowed to be hung upside down.

Arrow on the inlet and outlet chamber shows the direction of flow of liquid through the pump. Check whether the liquid can flow easily before starting pump.

Before pump installation, the inlet pipe line shall be cleaned. If there is impurities in pipe, it is necessary to install a strainer at 0.5-1m in front of the pump inlet (particularly recommended for pump with flow less than 8m3/h).

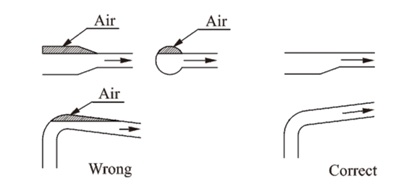

The air locks shall be avoided when installing the inlet pipe line. See fig below.

If the outlet globe valve might be closed( or the flow is decreased to be zero), a bypass shall be installed in outlet pipeline to ensure adequate lubricating and cooling water to pass the pump.

3, Electrical connection

3, Electrical connection

The electrical connections should be carried out by an authorized electrician.

To make sure the motor is suitable for the power supply, cables of the motor must be connected to power supply according to the motor nameplate.

Motor shall be connected with a fast and effective motor starter, to ensure that the motor will not be damaged by lack of phase, unstable voltage or overload. The motor shall be earthed reliably.

Caution: Before take apart the terminal box cover or dismantle pump. Make sure that the power supply is switched off.

2, Start-up, operation and maintenance

1, Do not start the pump until is has been filled with water pr liquid fully.

Fill water in pump in inverse pouring system.

Close the pump outlet valve, release air vent screw on the pump head, and open the inlet valve slowly until stable water flows from the air vent screw. The fasten the screw. Open the check valve completely in the inlet pipeline.

In open system, fill water in pump when liquid surface is lower than pump.

Notice: A check valve shall be installed in the inlet pipe.

Close the pump outlet valve, release air vent screw and fill the liquid in pump through the air vent screw hole until the pump and inlet pipe line are filled with water fully. Fasten the air vent screw again.

Caution: Do not start the pump until it has been filled with liquid fully and air vented. Be careful the direction of the air vent screw hole. Make sure the flowing water will not hurt persons or pump or its parts. Especially, prevent from hurting for the hot water application.

2, Check the rotary direction

Switch on the power supply and view the rotary direction by viewing the motor fan. Arrow on the pump head indicates the correct direction of rotation. That is, from the motor end, pump shall run counter-clockwise.

3, Check before pump start-up

Check whether the foundation bolt is fasten.

Check whether pump is filled with water fully.

Check whether the voltage of power supply is correct.

Check whether it turns correctly.

To make sure all pipe lines are connected tightly and can supply water normally.

The valves in the inlet pipe line are completely opened and the outlet valve shall be opened slowly after the pump is started up.

Check the operation pressure if pressure meter is installed.

Check all the controls for normal operation. If the pump is controlled by pressure switch, check and adjust the staring pressure and stopping pressure. Check the full load current to make sure it not surpasses the max.Current.

4, Frequency of pump starts

Pump should not be stared too frequently. It is suggested pump shall not be stared morn than 100 times per hour if the motor power is less or equal to 4kW. When motor power is big than 4kW, pump shall not be started morn than 20 times in one hour. If pump starts and stops too frequently, control device shall be checked and adjusted to make pump not start and stop frequently. Also, it is necessary to check the installation.

5, Suggestion: When pump running, flow should be controlled at the range of 0.5-1.3 times of rated flow.

6, Pump which is installed according to this installation manual will be work effectively and require a little maintenance.

Mechanical seal will be adjusted automatically, the moving part and stationary part is lubricated and cooled by the transferring liquid. When replace the mechanical seal, the user needn’t to disassemble the motor for power bigger than 7.5kW.

The bearing in pump is lubricated by the transferring liquid.

7, Frost Protecting

Pump can be used in the system with anti-frozen measures to water. If the pump is installed in easily frozen place, suitable antifreeze shall be added to the transferring liquid to prevent pump from being damaged. If antifreeze is not used, pump shall be stopped when it is frozen. Pumps which are not being used should be drained.

8, The following should be checked regularly from pump.

Pump working and operating pressure.

Possible leakage.

Possible motor overheat.

Cleaning/replacement of all strainers.

The switch off time of motor when overload.

Frequency of starts and stops.

All control operation.

If malfunction is found, check system according to “Fault finding and solution chart”

9, Pump shall be cleaned and kept appropriately when it is not used for a long time.

10, Pump shall be prevented from being corrupted and damaged in storage.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province