Lobe Pump

- Product Item : 071227001

- Category: Sewage Pump

- Pump Type: Positive Displacement Pump

- Self Head: Up to 9 meters

- Flow Rang: 1.5-3100 m3/h

- Head Rang:0-250 meters

Lobe pump, also named rotary lobe pump, is a type of positive displacement pump. The structure of lobe pump is similar to gear pump, but the lobes are not touch and turn each other, just almost meet.

Lobe pump without suction and discharge valves, is made up of rotating rotor and stationary pump body, changing the working space by the relative movement between the lobes and the pump body, and squeeze out the liquid by the rotating lobes, at the same time leave space on the other side, creating a low pressure, so that liquid is continuously sucked in.

Lobe pump can transfer various mediums, including but not limited to, solid, liquid and gas. It is an all-purpose pump which is widely used in various industries including beverage, food, chemical, pulp and paper.

Lobe Pump Design Featurer

● The wear-resistant plates in axial and

radial direction are replaceable, and the material can be specified.

● Particular designed helical lobe, make the pump more stable, and high efficient up to 90%. The self priming head of the lobe pump are up to 9 meters. And Yaness also produce straight blade lobe with various materials, like viton, rubber, HNBR, and stainless steel, etc.

● Double support construction R&D by Yaness, with high stability and pressure resistance up to 25 bar.

● Original design of intermediate isolation chamber, ensure the gearbox not be corrode by medium, even if the seal is lost efficacy.

● Yaness adopt unique sea and structure of the lobe pump, do not to need disassemble pipe to maintain.

● Bulit-in reduction gear is optional, for save floor space and cost.

● Shafts use 4140, 42CrMoTi or Monel alloy material.

● Adopt AGMA9 high standard gear.

● Yaness lobe pump adopt NO 220 closed gear oil, overheat & low over alarm device is an optional feature that is available.

● DDS modular design, symmetrical synchronous structure, positive and negative transfer is avliable, also can CIP (clean- in-place) and SIP (steam-in-place).

Lobe Pump Principle

● Vacuum Production

With lobes do synchronized relative motion, a space produce at cavity, and vacuum production at the inlet in the meantime.

● Inhalation of Medium

Medium will be suction to cavity after vacuum production.

● Full of Cavity

Medium will full of the cavity as the pump runs.

● Discharge Medium

The medium will press out of the pump chamber as the lobes continuous movement.

Lobe Pump Advantage

● High Flow

Straight channel design, like inline pump, improved the transfer performance. It’s with higher flow than other types pumps.

Flow rang: 0.5-5000m3/h

● High Pressure

The outlet pressure of single support type’s pump can reach 8 bar, double support type’s pump are 18 bar, and multistage pump can top to 30 bar.

● High Suction Pressure

The self head of Yaness lobe pump are up to 9 meters.

● High Integration

Yaness lobe pump with bulit-in reduction gear, compact structure, great save floor space.

● High Pasing Capacity

The lobe pump with high pasing capacity can transfer various types medium, the max dia passage is 80mm.

● High Efficiency

The energy consumption of Yaness lobe pump is only 65%-85% of other positive displacement pumps.

● High Viscosity

Yaness lobe pump not only can transport low viscosity medium, but also high viscosity medium, even million CP.

● Easy to Maintain

Online quick maintenance, do not need to replace pipe.

Lobe Pump Application

● Petroleum Industry

Crude oil, heavy oil, heavy oil, sludge,

fuel oil, polymers, solid-liquid-gas heterogeneous mixtures, suspended solids,

latex, etc., oil discharge, warehouse sweeping, etc.

● Environmental Protection

Feedwater lifting, municipal sewage, chemical waste water, scum debris, dehydrator feed, floater recovery, flocculant, activated carbon, primary sludge, digested sludge, dewatered sludge, sedimentation sludge.

● Chemical Industry

Shampoo, chemical raw materials, binders, acids, alkalis, other semi-finished products, finished products, alcohols, naphtha.

● Power Industry

Unit drainage tank drainage, low pressure oil supply, industrial wastewater, river water and sea water.

● Vacuum Drainage

Vacuum drainage and drainage of public places such as EMUs, railway stations, airports, subway stations, bus stations, parks, underground venues, civil buildings, etc.

● Paper Industry

Pulp, suspension, polyacrylamide, calcium carbonate, starch paste, rosin, filler, dry strength agent, wet strength agent, sizing agent, poor filter, defoamer, coating, water treatment chemicals.

● Pharmaceuticals Industry

Various plasters, extracts, medicinal emulsions, pill pastes, syrups, health products liquids and pastes, pharmaceuticals, etc.

● Food Industry

Patrol, condensed milk, yogurt, concentrated fruit juice, honey, syrup, sucrose, tomato juice, jam, ice cream, milk, yeast slurry, meat slurry, fruit smelt, soybean protein, seasoning, lees, flour slurry.

● Commodity Production

AES, LAS, AOS, K12, Glycerin, Sorbitol, Fatty Alcohol, Sulfate, Facial Cleanser, Dishwashing Liquid, Dishwashing Liquid, Shower Gel, Toothpaste, Soap.

● Agricultural Industry

Organic fertilizer, mash feed, farm excreta, waste water, waste liquid, etc.

● Shipping Industry

Cruise and terminal domestic sewage, warehouse bottom sludge, lubricating oil, crude oil, transportation of chemical raw materials and oil spill recovery at sea, etc.

● Paint Industry

Paint, coating, ink, resin, insulating paint and organic solvent, etc.

● Chemical Fiber Industry

Viscose paste, vinylon paste, acrylic pulp, spandex pulp, polyester chips, functional fibers, rayon, polypropylene, semi-finished leather, PVA.

● Municipal

Irrigation relief, drainage and rescue,.

● Fire Fighting Foam

Intelligent fire truck, fire foam liquid pump, fire pump, fire emergency water intake, fire water supply, vehicle foam pump, foam proportioning pump.

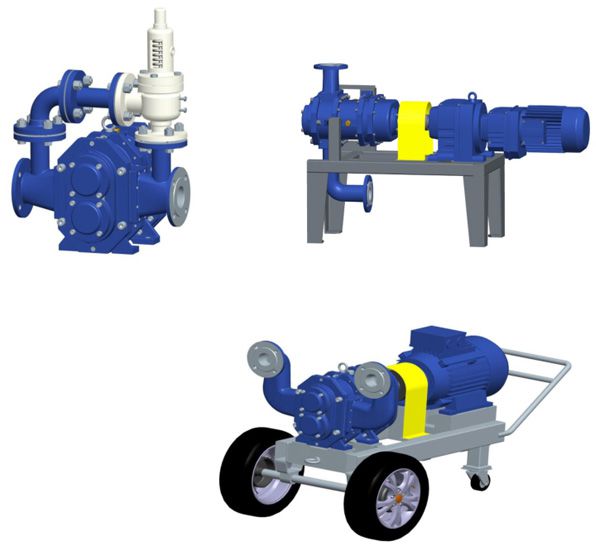

Yaness Lobe Pump Type

|

Model |

Flow(L/RPM) |

Flow Rang(m3/h) |

Head Rang(m) |

Self Head(m) |

Speed(RPM) |

|

HDB25 |

0.1395 |

1.5-5 |

0-180 |

0-9.0 |

10-720 |

|

HDB40 |

0.2304 |

5-10 |

0-160 |

0-9.0 |

10-640 |

|

HDB50 |

0.392 |

10-15 |

0-160 |

0-9.0 |

10-550 |

|

HDB65X |

0.6405 |

12-25 |

0-30 |

0-3.5 |

10-550 |

|

HDB65D |

1.0125 |

15-36 |

0-280 |

0-9.0 |

10-550 |

|

HDB80 |

1.857 |

36-60 |

0-180 |

0-9.0 |

10-550 |

|

HDB100 |

2.864 |

60-100 |

0-100 |

0-9.0 |

10-500 |

|

HDB125 |

4.566 |

100-150 |

0-200 |

0-9.0 |

10-500 |

|

HDB150 |

6.828 |

150-200 |

0-160 |

0-9.0 |

10-550 |

|

HDB200X |

9.456 |

200-310 |

0-100 |

0-6.0 |

10-550 |

|

HDB200D |

12.5 |

250-350 |

0-250 |

0-9.5 |

10-500 |

|

HDB250 |

18.33 |

350-450 |

0-180 |

0-9.0 |

10-510 |

|

HDB300 |

25 |

450-650 |

0-120 |

0-9.0 |

10-510 |

|

HDB350 |

37.5 |

650-1000 |

0-80 |

0-5.0 |

10-500 |

|

HDB350-G |

46.056 |

800-1800 |

0-160 |

0-8.5 |

10-500 |

|

HDB400 |

43.75 |

1000-1400 |

0-80 |

0-5.0 |

10-550 |

|

HDB450 |

50 |

1400-2100 |

0-60 |

0-5.0 |

10-550 |

|

HDB500 |

141.5 |

2100-3000 |

0-100 |

0-8.0 |

10-510 |

Yaness have morn than 30 years’ production and sales experience in rotary lobe pump, what we provide isn’t only good price, but better product quality and satisfied after-sales service.

Click here to learn more about rotary lobe pump.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province