Company news

Chemical Pump Manual

Chemical Pump Manual

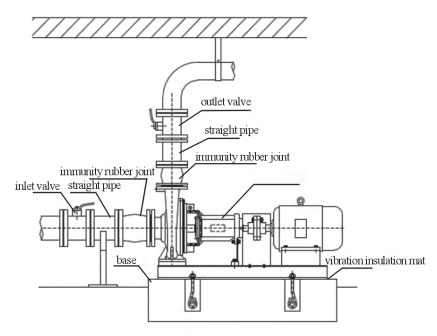

Installation

Installation

1, Pump should be sited in a well ventilated and frost-free position.

2, Suction pipes should be as short as possible and it should prevent from air pockets.

3, When install pipelines, ensure not let pipelines force on the pump to prevent from pump twisted, and the base of the pump set shall be stable and balanced.

4, Electric devices should ensure pump not to be damaged by lack phase, unstable voltage, electric leakage , overload, etc.

5, Center of motor shaft and pump shaft should be on the same beeline.

Operation

1, Open inlet valve, open outlet valve a little, make sure casing is full filled with liquid to prevent it from dry rubbing to damage the mechanical seal.

2, Start motor, check rotation, open outlet valve gradually to the requirement.

3, Note that pump should rotate without noise, run reliable, if abnormal, stop and check and repair.

4, According to the pump running condition and period, check pump situation, leak, motor temperature periodically.

Assemble and dissemble

1, Press bearing to shaft on the position, put them in the bearing housing, then fit the bearing plate with oil seal, tighten screws.

2, Press stationary part of mechanical seal to the casing cover, then fit the casing cover into the bearing housing, fit rotating part of mechanical seal on the shaft. (Mechanical seal faces should be clean and lubricated.)

3, Fit key and impeller on the shaft, fit gasket, fasten the nut.

3, Fit key and impeller on the shaft, fit gasket, fasten the nut.

4, Fit O-ring and casing on casing cover, fasten screw, rotate shaft, it should be free, no block and no metal rubbing noise.

5, Fit the motor with coupling on the base, screw base screws, but not fasten, then, fit the pump with key and coupling on the base.

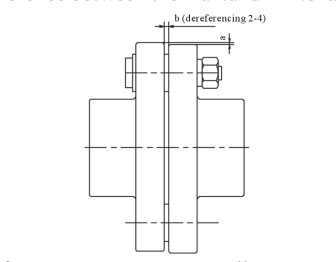

6, Adjust motor and pump, fasten base crews from motor and pump, then, fasten the fastening screw for coupling. And limit the a, b dimensions in the following figure. a is measured around the circum of the coupling. And shall not exceed 0.2mm; b is also measured around circum of the coupling, and the measured figure difference between the max, and min. shall not exceed.

7, Fit supporter, fasten screws, rotate coupling, rotator should be free. It should be not felt loose or locked. Reverse the above steps to dissemble a pump set.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province