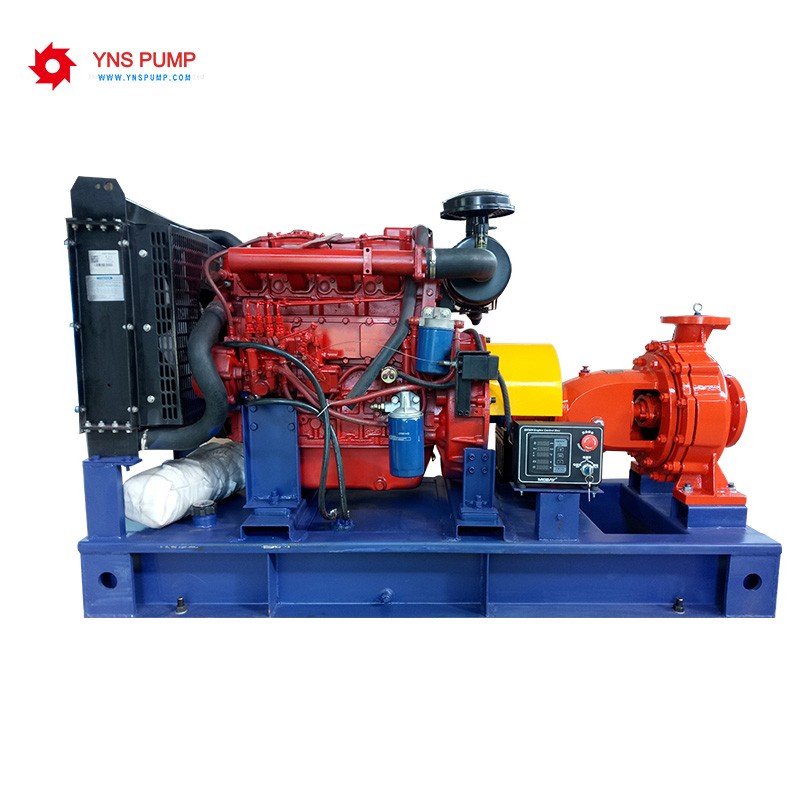

Single Stage End Suction Booster Pump For Fire Fighting With Diesel Engine

- Product Item : 071028001

- Category: Booster Pump

- Material: Cast iron, SS304L, SS316L

- Flow: 2-400m³/h

- Head: 9.6-125m

- Power: 0.55-110kW

The IS and IR pumps with diesel engine are horizontal single-stage single-suction clear water centrifugal pumps for industrial and agricultural and urban, drainage, fire water supply and so on. It is used to suck water and physicochemical properties similar to water without solid particles. It is widely used in industrial and agricultural and urban, drainage, fire water supply and so on. The IS and IR pumps are designed according to the performance and size specified in the international standard IS02858. The technical standards are close to the international standards and reach the international advanced level. It is one of the energy-saving pump products promoted in China. The pump has the advantages of simple structure, reliable performance, small volume, light weight, good anti-cavitation performance, low power consumption and convenient use and maintenance. IS and IR pumps have wide versatility. There are 140 specifications in the whole series, but only four types of shafts are used; shafts, bearings and shaft seals of the same specification can be interchanged; there are only four types of suspensions for the whole series of pumps. The pump speed is divided into 2900 and 1450 rev / min. The performance is as follows: 2900 rev / min 1450 rev / min large flow: 240 m 3 / min 400 m 3 / min high total head: 125 m 55 m high speed: 3500 rev / min (for 60 wave power supply, impeller diameter Reduced) High operating temperature: 80 ° C allows the suction line pressure of 0.3 MPa, the pump's high operating pressure of 1.6 MPa.

Advantage

● IS type single-stage single-suction centrifugal pump is designed according to the performance and size specified in the international standard ISO2858. It is mainly composed of pump body, pump cover, impeller, shaft, seal ring, bushing and suspension bearing.● The end suction booster pump body and pump cover part of the IS type single-stage single-suction centrifugal pump are divided from the back of the impeller, which is commonly referred to as the rear door structure. The utility model has the advantages that the maintenance is convenient, the pump body is not moved during the maintenance, the suction pipeline, the discharge pipeline and the electric motor are removed, and only the intermediate coupling member of the extension coupling is removed, and the rotor portion can be taken out for maintenance.

● The booster pump housing (ie pump body and pump cover) forms the working chamber of the pump. Impellers, shafts and rolling bearings are the rotors of the pump. The suspension bearing component supports the rotor portion of the pump, which is subjected to the radial and axial forces of the pump.

● In order to balance the axial force of the pump, most of the impellers of the pump are provided with a sealing ring at the front and the rear, and a balance hole is arranged on the rear cover of the impeller. Since some pumps have little axial force, the back of the impeller is not sealed. Ring and balance holes.

● The axial seal ring of the pump is composed of packing gland, packing ring and packing to prevent air intake or a large amount of water leakage. If the impeller of the pump is balanced, the cavity with the soft packing communicates with the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter the air along the surface of the sleeve. Therefore, a packing ring is inserted in the filling chamber. A small hole in the pump cover guides the pressurized water in the pump chamber to the packing ring for sealing. If the impeller of the pump has no balance hole, since the liquid pressure on the back of the impeller is greater than atmospheric pressure, there is no gas leakage problem, so the packing ring may not be installed.

● In order to avoid shaft wear, bushing protection is provided at the part of the shaft passing through the packing cavity. An O-ring seal is provided between the sleeve and the shaft to prevent air intake or water leakage along the mating surface.

● The transmission mode of the pump is connected to the motor by lengthening the elastic coupling. The rotation direction of the pump is rotated clockwise from the driving end.

Application

● The IS and IR end suction pump are horizontal single-stage single-suction clear water centrifugal pumps for industrial and agricultural and urban, drainage, fire water supply and so on.● It is used to suck water and physicochemical properties similar to water without solid particles. It is widely used in industrial and agricultural and urban, drainage, fire water supply and so on.

● The IS and IR fire fighting pumps are designed according to the performance and size specified in the international standard IS02858. The technical standards are close to the international standards and reach the international advanced level. It is one of the energy-saving pump products promoted in China.

● The single stage end suction booster pump has the advantages of simple structure, reliable performance, small volume, light weight, good anti-cavitation performance, low power consumption and convenient use and maintenance.

Structure description

● The IS and IR singe stage pumps are designed according to the performance and dimensions specified in the national standard ISO2858. They are mainly composed of pump body, pump cover, impeller, shaft, seal ring, bushing and suspension bearing components.● The booster pump body and the pump cover of the IS and IR pumps are divided from the back of the impeller, which is commonly referred to as the rear door structure. The utility model has the advantages that the maintenance is convenient, the pump body is not moved during the maintenance, the suction pipeline, the discharge pipeline and the electric motor are removed, and only the intermediate coupling of the extension coupling is removed, and the rotor component can be withdrawn for maintenance.

● The pump housing (ie pump body and pump cover) constitutes the pump's working chamber, impeller, shaft and rolling bearings, etc. The suspension bearing component supports the rotor component of the pump, and the rolling bearing is subjected to the radial and axial forces of the pump.

● In order to balance the axial force of the pump, most of the pump impellers are provided with a sealing ring on the front and rear, and a balance hole is arranged on the rear cover of the impeller. Since some pumps have little axial force, there is no seal ring on the back of the impeller. Balance the holes.

● The axial seal ring of the pump is composed of a packing gland, a packing ring, and a packing to prevent intake air or a large amount of water leakage. The pump impeller is balanced. The cavity with the soft filler is connected to the suction port of the impeller. If the liquid at the inlet of the impeller is in a vacuum state, it is easy to enter the air along the surface of the sleeve. Therefore, a packing ring is installed in the filling chamber through the small hole in the pump cover. The pressure water in the pump chamber is led to the packing ring for sealing. If the impeller of the pump has no balance hole, since the liquid pressure on the back of the impeller is greater than atmospheric pressure, there is no gas leakage problem, so the packing ring may not be installed.

● In order to avoid shaft wear, bushing protection is provided at the part of the shaft passing through the packing cavity, and an O-ring seal is arranged between the bushing and the shaft to prevent air intake or water leakage along the mating surface.

● The pump is driven by an elongated flexible coupling that is coupled to the motor. The direction of rotation of the pump, viewed from the drive end, rotates clockwise.

Maintenance

As long as the maintenance knows the mechanical structure, the clean water centrifugal pump is a simple machine. Maintenance should be used within the rated range, can not run at no load, pay attention to avoid cavitation and steam binding, strengthen inspections, and timely replace worn seal components.

● Check the clean water centrifugal pump pipeline and joints for looseness. Turn the clear water centrifugal pump by hand to see if the clear water centrifugal pump is flexible.

● Add bearing lubrication oil to the bearing body, observe that the oil level should be at the center line of the oil mark, and the lubricating oil should be replaced or replenished in time.

● Unscrew the water plug screw of the pump body of the clean water centrifugal pump and infuse the water.

● Close the gate valve and outlet pressure gauge of the outlet pipe.

● Jog motor, Wuxi welded pipe to see if the motor steering is correct.

● Start the motor. When the clean water centrifugal pump is running normally, open the outlet pressure gauge and gradually open the gate valve and check the motor load condition after it shows the appropriate pressure.

● Try to control the flow and head of the clear water centrifugal pump within the range indicated on the sign to ensure that the centrifugal pump runs at the highest efficiency point to obtain the maximum energy saving effect.

● During the operation of the clean water centrifugal pump, the bearing temperature should not exceed the ambient temperature of 35 °C, and the maximum temperature of the tin-free welded pipe should not exceed 80 °C.

● If the clear water centrifugal pump is found to have abnormal sound, stop immediately and check the cause.

● When the clean water centrifugal pump is to be stopped, first close the gate valve and pressure gauge, then stop the motor.

● The clear water centrifugal pump will change the lubricating oil after 100 hours in the first month of operation, and then change the oil once every 500 hours.

● Regularly adjust the packing gland to ensure that the dripping in the packing chamber is normal.

● Regularly check the wear of the bushings and replace them in time after the wear is large.

● When the clean water centrifugal pump is used in the cold winter season, after parking, the water plug of the lower part of the pump body should be unscrewed to release the medium. Prevent freezing cracks.

● The clear water centrifugal pump has long-term suspension of the Wuxi welded pipe. It is necessary to disassemble the pump completely, wipe off the moisture, and apply the grease to the rotating part and the joint, and keep it in a safe place.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province