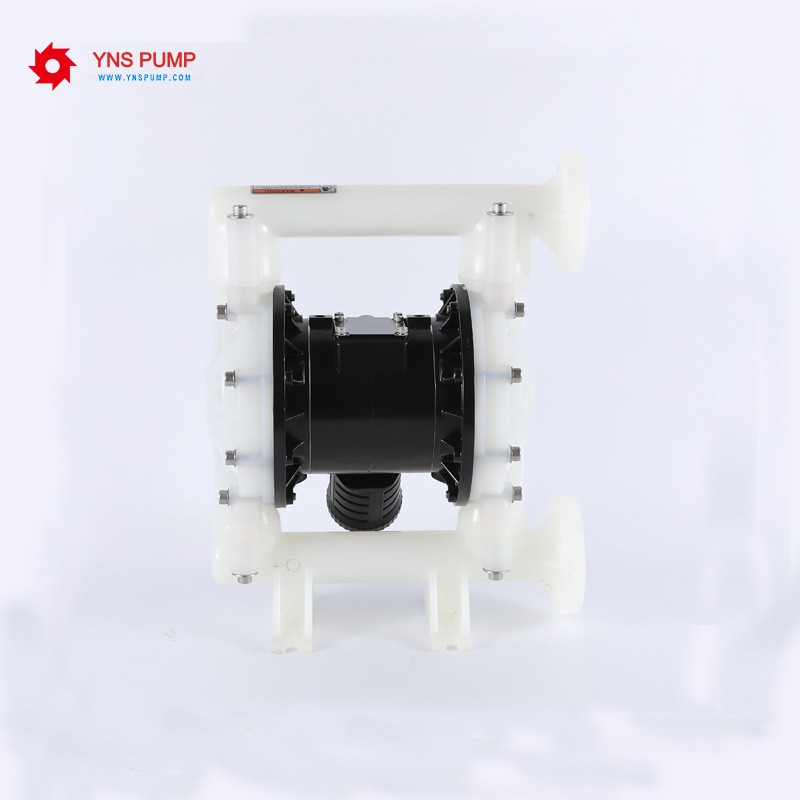

Plastic Pneumatic Diaphragm Pump With 8.4 bar Pressure

- Product Item : 071029001

- Category: Diaphragm Pump

- Max.pressure: 8.4 bar

- Main body material: PP, Acetal, PVDF, Aluminum alloy, 304SST, 316SST

- Size: 1/4”,1/2”,3/4”,1”,1.5”,2”,3”

- Connect: NPT/BSTP/Flange

The Plastic Pneumatic Diaphragm Pump is the third generation of pneumatic diaphragm pump developed by YANESS. It has six advantages of reliable quality, long service life, low noise floor, low vibration, high lift, never crash, and fine workmanship. Working principle: in diaphragm pump The two symmetrical working chambers are each provided with a flexible diaphragm, and the connecting rods form the two diaphragms into one body. After the compressed air enters the valve from the intake joint of the pump, the diaphragm in the two working chambers is pushed to drive The two diaphragms of the link are synchronized. At the same time, the gas in the other working chamber exits the pump from the back of the diaphragm. Once the end of the trip is reached. The valve train automatically introduces compressed air into the other working chamber, pushing the diaphragm in the opposite direction, thus forming a synchronous reciprocating motion of the two diaphragms. Two one-way ball valves are arranged in each working chamber, and the reciprocating motion of the diaphragm causes a change in the inner volume of the working chamber, forcing the two one-way ball valves to be alternately opened and closed, thereby continuously sucking in and discharging the liquid.

● The pneumatic pump is reliable and low in flammable and explosive environment, such as fuel, gunpowder and explosive. Because: first, it is impossible to generate spark after grounding; second, no heat is generated during work, the machine does not Will overheat; third, the fluid will not overheat because the diaphragm pump has less agitation of the fluid.

● In places with poor construction sites, such as construction site, industrial and mining wastewater discharge, due to the impurities in the sewage and complex components, the pipeline is prone to blockage, so that the load on the electric pump is too high, and the motor is hot and vulnerable. The pneumatic diaphragm pump can pass through the particles and the flow rate is adjustable, and the pipe is automatically stopped to be unobstructed when the pipe is blocked.

● In addition, the diaphragm pump is small in size and easy to move. It does not require a foundation, and it occupies a very small ground. It is simple and economical to install. Can be used as a mobile material transfer pump.

● In the treatment of hazardous and corrosive materials, the diaphragm pump can completely separate the material from the outside world.

● or in some tests to ensure that no impurities contaminated raw materials.

● can be used to transport fluids with relatively unstable chemical properties, such as: photosensitive materials, flocculation liquids, etc. This is because the diaphragm pump has a low shear force and a small physical impact on the material.

● Pump paint, gums, pigments, adhesives and glue.

● Pumping all kinds of tiles, porcelain, bricks and pottery glaze.

● Pump various abrasives, corrosive agents, cleaning grease and so on.

● Pumping a variety of highly toxic, flammable, volatile liquids.

● Pumping all kinds of sewage, cement grout and mortar.

● Pumping a variety of strong acids, strong alkalis, strong corrosive liquids, etc.

● Use the pump as the tanker, and the barge clears the tank to absorb the sewage.

● Various high temperature liquids can withstand up to 150 °C.

Features

Features

● The pneumatic pump is reliable and low in flammable and explosive environment, such as fuel, gunpowder and explosive. Because: first, it is impossible to generate spark after grounding; second, no heat is generated during work, the machine does not Will overheat; third, the fluid will not overheat because the diaphragm pump has less agitation of the fluid.

● In places with poor construction sites, such as construction site, industrial and mining wastewater discharge, due to the impurities in the sewage and complex components, the pipeline is prone to blockage, so that the load on the electric pump is too high, and the motor is hot and vulnerable. The pneumatic diaphragm pump can pass through the particles and the flow rate is adjustable, and the pipe is automatically stopped to be unobstructed when the pipe is blocked.

● In addition, the diaphragm pump is small in size and easy to move. It does not require a foundation, and it occupies a very small ground. It is simple and economical to install. Can be used as a mobile material transfer pump.

● In the treatment of hazardous and corrosive materials, the diaphragm pump can completely separate the material from the outside world.

● or in some tests to ensure that no impurities contaminated raw materials.

● can be used to transport fluids with relatively unstable chemical properties, such as: photosensitive materials, flocculation liquids, etc. This is because the diaphragm pump has a low shear force and a small physical impact on the material.

Main purpose:

Main purpose:

● Pump paint, gums, pigments, adhesives and glue.

● Pumping all kinds of tiles, porcelain, bricks and pottery glaze.

● Pump various abrasives, corrosive agents, cleaning grease and so on.

● Pumping a variety of highly toxic, flammable, volatile liquids.

● Pumping all kinds of sewage, cement grout and mortar.

● Pumping a variety of strong acids, strong alkalis, strong corrosive liquids, etc.

● Use the pump as the tanker, and the barge clears the tank to absorb the sewage.

● Various high temperature liquids can withstand up to 150 °C.

● As a pre-stage pressure supply device for various solid-liquid separation devices.

Technical parameters

| Mode | Max.Suction Lift (dry\wet,m) | Max. particle diameter (mm) | Suction and discharge size (inch) | Air inlet size (inch) | Max. flow rate (L/min) | Max. air consumption (m3/min) |

| YRO-15/20 | 4 \ 7.6 | 2.5 | 1/2 3/4 | 1/4 | 57 | 0.672 |

| YRO-25 | 4 \ 8 | 4 | 1 | 1/2 | 157 | 1.7 |

| YRO-40 | 5 \ 8 | 5 | 1½ | 1/2 | 358 | 3.5 |

| YRO-50 | 5 \ 8 | 6 | 2 | 1/2 | 587 | 4.9 |

| YRO-80 | 5 \ 8 | 9.4 | 3 | 3/4 | 1060 | 9.1 |

Reference

1, Aluminium Alloy Pneumatic Diaphragm Pump

2, Stainless Steel Pneumatic Diaphragm Pump