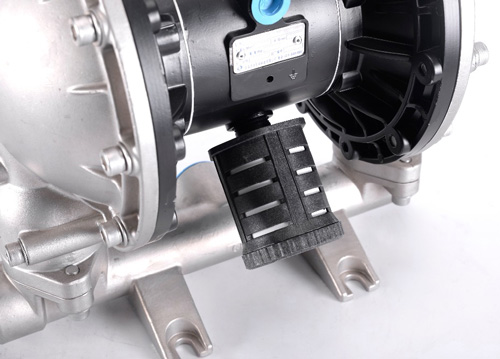

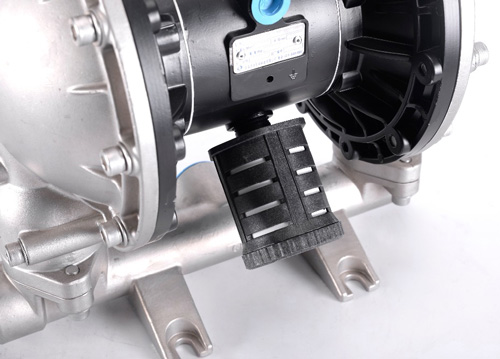

Portable Stainless Steel Pneumatic Diaphragm Pump with Teflon Diaphragm

- Product Item : 071029003

- Category: Diaphragm Pump

- Max.pressure: 8.4 bar

- Main body material: PP, Acetal, PVDF, Aluminum alloy, 304SST, 316SST

- Size: 1/4”,1/2”,3/4”,1”,1.5”,2”,3”

- Connect: NPT/BSTP/Flange

The Stainless Steel Pneumatic Diaphragm Pump can pump both flowing liquid and some non-flowable medium. It has many advantages of submersible pumps, self-priming pumps, impurity pumps, shield pumps, mud pumps and other conveying machinery.

● No need to irrigate water. Suction up to 8m. Lift up to 84m. The outlet pressure is ≥ 8.4 bar.

● The flow is spacious and the performance is good. Allow large diameters up to 10mm. Pumping mud, impurities, and wear on the pump;

● The head and flow can be adjusted steplessly through the opening of the valve;

● The pump has no rotating parts, no shaft seal, and the pumped medium such as the pneumatic diaphragm pump is completely separated from the moving parts of the pump and the workpiece medium, and the conveyed medium does not leak outward. Therefore, when pumping toxic, easy to play or corrosive media, it will not cause environmental pollution and endanger personal safety;

● No need to use electricity. Safe and reliable in flammable and explosive places;

● Can be submerged in the medium to work;

● Easy to use, reliable, open and stop, simply open and close the gas valve. Even if there is no medium running or a sudden stop due to unexpected conditions, the pump will not be damaged. Once overloaded, the pump will stop from the ground and have self-protection performance. When the load returns to normal, it can automatically start running.

● The structure is simple and the wearing parts are few. The pump has simple structure, convenient installation and maintenance, and the medium conveyed by the pump does not touch the moving parts such as the valve, the connecting rod, etc., unlike other types of pumps due to the rotor, piston and gear. The wear of the blades and other components causes the performance to gradually decrease:

● It can transport a relatively viscous liquid (viscosity below 10,000 centipoise);

● The pump does not need to be lubricated with oil, even if it is idling. It also has no effect on the pump, which is a big feature of the pump.

Features

Features

● Stainless steel pneumatic diaphragm pump is powered by air, so the flow rate is automatically adjusted with the change of back pressure (outlet resistance), suitable for medium and high viscosity fluids. The working point of the centrifugal pump is set on the basis of water. If it is used for fluid with a slightly higher viscosity, it needs to be equipped with a reducer or a frequency converter. The cost is greatly improved, and the same is true for the gear pump.

● In the flammable and explosive environment, the pneumatic pump is reliable and low in cost, such as the transportation of fuel and gunpowder, because: first, it is impossible to generate spark after grounding; second, no heat is generated during work, the machine will not overheat Third, the fluid does not overheat because the diaphragm pump has a small amount of agitation of the fluid.

● In places with poor construction sites, such as construction site, industrial and mining wastewater discharge, due to the impurities in the sewage and complex components, the pipeline is prone to blockage, so that the load on the electric pump is too high, and the motor is hot and vulnerable. The pneumatic diaphragm pump can pass through the particles and the flow rate is adjustable, and the pipe is automatically stopped to be unobstructed when the pipe is blocked.

● In addition, the pneumatic diaphragm pump is small in size, easy to move, does not require foundation, and occupies a very small ground, and is easy and economical to install. Can be used as a mobile material transfer pump.

● In hazardous and corrosive materials handling, the diaphragm pump completely separates the material from the outside world.

● Or in some tests to ensure that no impurities contaminate the raw materials.

● It can be used to transport fluids with relatively unstable chemical properties, such as photosensitive materials, flocculation liquids, etc. This is because the diaphragm pump has a low shear force and a small physical impact on the material.

Working principle

The stainless steel pneumatic diaphragm pump is powered by compressed air. It is a volumetric pump caused by the reciprocating deformation of the diaphragm. Its working principle is similar to that of the plunger pump. Due to the working principle of the diaphragm pump, the diaphragm pump has the following characteristics:

● Stainless steel pneumatic diaphragm pump will not overheat: compressed air is used as power, and it is a process of expansion and heat absorption when exhausting. When the pneumatic pump works, the temperature is reduced, and no harmful gas is discharged.

● No sparks are generated: the pneumatic diaphragm pump does not use electric power for power, and prevents static sparks after grounding.

● It can pass the liquid containing particles: because it is volumetric and the inlet is a ball valve, it is not easy to be blocked.

● The shearing force on the material is extremely low: how to suck in when working, so the agitation of the material is small, suitable for the transport of unstable materials.

● The flow rate can be adjusted, and a throttle valve can be added at the material outlet to adjust the flow rate.

● Has the function of self-priming.

● Can run empty without danger.

● Can work diving.

● The fluids that can be transported are extremely wide, from low viscosity to high viscosity, and viscous from corrosive.

● No complicated control system, no cables, fuses, etc.

● Small size, light weight and easy to move.

● No lubrication is required, so maintenance is easy and there is no pollution to the working environment due to dripping.

● The pump is always efficient and will not be degraded by wear.

● One hundred percent of energy utilization, when the outlet is closed, the pump automatically stops, the equipment moves, wears, overloads, heats up

● There is no dynamic seal, and the maintenance is simple to avoid leakage. There is no dead point when working.

Application

Application

● Stainless steel pneumatic diaphragm pumping peanut butter, kimchi, mashed potatoes, small red sausage, jam apple pulp, chocolate, etc.

● Pump paint, gum, pigment.

● Adhesives and glues, all types can be pumped.

● All kinds of tiles, porcelain, bricks and pottery glaze.

● After the oil well is drilled, pump the sediment and grout.

● Pump various emulsions and fillers.

● Pump all kinds of sewage.

● Use the pump as the tanker, and the barge clears the tank to absorb the sewage.

● Hops and fermented powder slurry, syrup, sugar dense.

● Pumping water from mines, tunnels, tunnels, beneficiation, and slag. Pumping cement grout and mortar.

● Various rubber pulps.

● Various abrasives, corrosives, oil and mud, cleaning grease and general containers.

● A variety of highly toxic, flammable, volatile liquids.

● A variety of strong acids, strong bases, strong corrosive liquids.

● Various high temperature liquids can withstand up to 150 °C.

● No need to irrigate water. Suction up to 8m. Lift up to 84m. The outlet pressure is ≥ 8.4 bar.

● The flow is spacious and the performance is good. Allow large diameters up to 10mm. Pumping mud, impurities, and wear on the pump;

● The head and flow can be adjusted steplessly through the opening of the valve;

● The pump has no rotating parts, no shaft seal, and the pumped medium such as the pneumatic diaphragm pump is completely separated from the moving parts of the pump and the workpiece medium, and the conveyed medium does not leak outward. Therefore, when pumping toxic, easy to play or corrosive media, it will not cause environmental pollution and endanger personal safety;

● No need to use electricity. Safe and reliable in flammable and explosive places;

● Can be submerged in the medium to work;

● Easy to use, reliable, open and stop, simply open and close the gas valve. Even if there is no medium running or a sudden stop due to unexpected conditions, the pump will not be damaged. Once overloaded, the pump will stop from the ground and have self-protection performance. When the load returns to normal, it can automatically start running.

● The structure is simple and the wearing parts are few. The pump has simple structure, convenient installation and maintenance, and the medium conveyed by the pump does not touch the moving parts such as the valve, the connecting rod, etc., unlike other types of pumps due to the rotor, piston and gear. The wear of the blades and other components causes the performance to gradually decrease:

● It can transport a relatively viscous liquid (viscosity below 10,000 centipoise);

● The pump does not need to be lubricated with oil, even if it is idling. It also has no effect on the pump, which is a big feature of the pump.

Features

Features● Stainless steel pneumatic diaphragm pump is powered by air, so the flow rate is automatically adjusted with the change of back pressure (outlet resistance), suitable for medium and high viscosity fluids. The working point of the centrifugal pump is set on the basis of water. If it is used for fluid with a slightly higher viscosity, it needs to be equipped with a reducer or a frequency converter. The cost is greatly improved, and the same is true for the gear pump.

● In the flammable and explosive environment, the pneumatic pump is reliable and low in cost, such as the transportation of fuel and gunpowder, because: first, it is impossible to generate spark after grounding; second, no heat is generated during work, the machine will not overheat Third, the fluid does not overheat because the diaphragm pump has a small amount of agitation of the fluid.

● In places with poor construction sites, such as construction site, industrial and mining wastewater discharge, due to the impurities in the sewage and complex components, the pipeline is prone to blockage, so that the load on the electric pump is too high, and the motor is hot and vulnerable. The pneumatic diaphragm pump can pass through the particles and the flow rate is adjustable, and the pipe is automatically stopped to be unobstructed when the pipe is blocked.

● In addition, the pneumatic diaphragm pump is small in size, easy to move, does not require foundation, and occupies a very small ground, and is easy and economical to install. Can be used as a mobile material transfer pump.

● In hazardous and corrosive materials handling, the diaphragm pump completely separates the material from the outside world.

● Or in some tests to ensure that no impurities contaminate the raw materials.

● It can be used to transport fluids with relatively unstable chemical properties, such as photosensitive materials, flocculation liquids, etc. This is because the diaphragm pump has a low shear force and a small physical impact on the material.

Working principle

The stainless steel pneumatic diaphragm pump is powered by compressed air. It is a volumetric pump caused by the reciprocating deformation of the diaphragm. Its working principle is similar to that of the plunger pump. Due to the working principle of the diaphragm pump, the diaphragm pump has the following characteristics:

● Stainless steel pneumatic diaphragm pump will not overheat: compressed air is used as power, and it is a process of expansion and heat absorption when exhausting. When the pneumatic pump works, the temperature is reduced, and no harmful gas is discharged.

● No sparks are generated: the pneumatic diaphragm pump does not use electric power for power, and prevents static sparks after grounding.

● It can pass the liquid containing particles: because it is volumetric and the inlet is a ball valve, it is not easy to be blocked.

● The shearing force on the material is extremely low: how to suck in when working, so the agitation of the material is small, suitable for the transport of unstable materials.

● The flow rate can be adjusted, and a throttle valve can be added at the material outlet to adjust the flow rate.

● Has the function of self-priming.

● Can run empty without danger.

● Can work diving.

● The fluids that can be transported are extremely wide, from low viscosity to high viscosity, and viscous from corrosive.

● No complicated control system, no cables, fuses, etc.

● Small size, light weight and easy to move.

● No lubrication is required, so maintenance is easy and there is no pollution to the working environment due to dripping.

● The pump is always efficient and will not be degraded by wear.

● One hundred percent of energy utilization, when the outlet is closed, the pump automatically stops, the equipment moves, wears, overloads, heats up

● There is no dynamic seal, and the maintenance is simple to avoid leakage. There is no dead point when working.

Application

Application● Stainless steel pneumatic diaphragm pumping peanut butter, kimchi, mashed potatoes, small red sausage, jam apple pulp, chocolate, etc.

● Pump paint, gum, pigment.

● Adhesives and glues, all types can be pumped.

● All kinds of tiles, porcelain, bricks and pottery glaze.

● After the oil well is drilled, pump the sediment and grout.

● Pump various emulsions and fillers.

● Pump all kinds of sewage.

● Use the pump as the tanker, and the barge clears the tank to absorb the sewage.

● Hops and fermented powder slurry, syrup, sugar dense.

● Pumping water from mines, tunnels, tunnels, beneficiation, and slag. Pumping cement grout and mortar.

● Various rubber pulps.

● Various abrasives, corrosives, oil and mud, cleaning grease and general containers.

● A variety of highly toxic, flammable, volatile liquids.

● A variety of strong acids, strong bases, strong corrosive liquids.

● Various high temperature liquids can withstand up to 150 °C.

● As a front stage pressure supply device for various solid-liquid separation devices.

Technical parameters

| Mode | Max.Suction Lift (dry\wet,m) | Max. particle diameter (mm) | Suction and discharge size (inch) | Air inlet size (inch) | Max. flow rate (L/min) | Max. air consumption (m3/min) |

| YRO-15/20 | 4 \ 7.6 | 2.5 | 1/2 3/4 | 1/4 | 57 | 0.672 |

| YRO-25 | 4 \ 8 | 4 | 1 | 1/2 | 157 | 1.7 |

| YRO-40 | 5 \ 8 | 5 | 1½ | 1/2 | 358 | 3.5 |

| YRO-50 | 5 \ 8 | 6 | 2 | 1/2 | 587 | 4.9 |

| YRO-80 | 5 \ 8 | 9.4 | 3 | 3/4 | 1060 | 9.1 |

Reference

1, Plastic Pneumatic Diaphragm Pump

2, Aluminium Alloy Pneumatic Diaphragm Pump