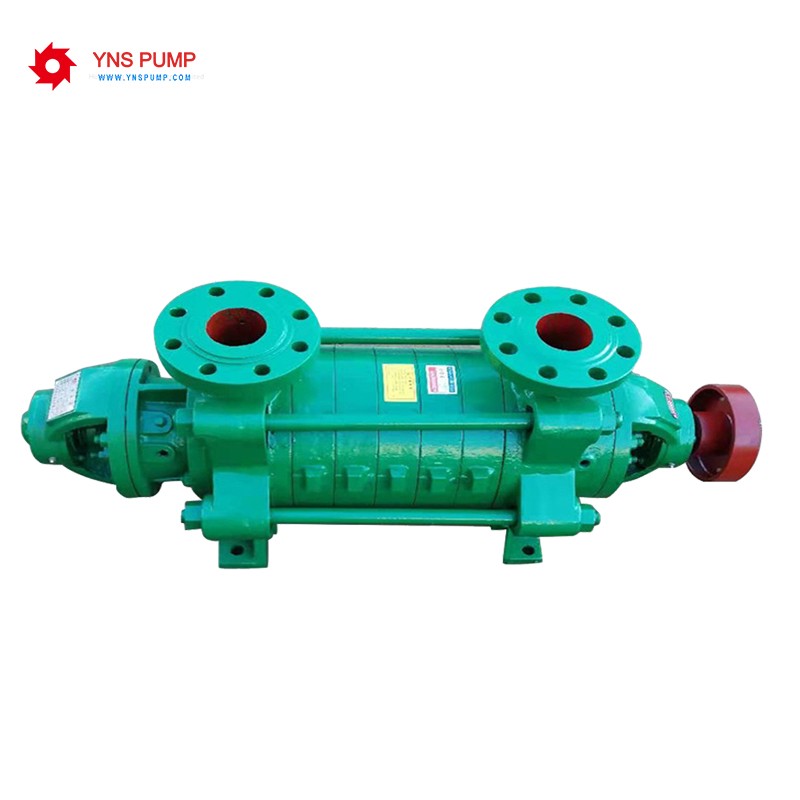

Horizontal Multistage Centrifugal Pumps

- Product Item : HMCP

- Category: Booster Pump

- Type: Multistage Centrifugal Pumps

- Material: Cast iron, cast steel, SS304, SS316

- Brand: YANESS

Horizontal Multistage Centrifugal Pumps are pumps designed to efficiently transfer fluids, such as water or oil, by converting kinetic energy into pressure energy. These pumps have multiple impeller stages that work in tandem to generate high pressure and flow rates, making them suitable for a wide range of applications.

At YANESS, we offer a range of Horizontal Multistage Centrifugal Pumps designed to meet the needs of different industries and applications.

Applications and Industries

Horizontal Multistage Centrifugal Pumps are used in various applications and industries due to their versatility and efficiency. Here are some more details about these applications and initiatives:

l Water supply and distribution: Horizontal Multistage Centrifugal Pumps are commonly used in water supply and distribution systems to pump water from a source, such as a well or reservoir, to a distribution network. They are also used to boost the pressure in the network to ensure a consistent water supply to consumers.

l Irrigation and agriculture: Horizontal Multistage Centrifugal Pumps are used in irrigation systems to pump water from a source to the crops. They are also used to increase the pressure and flow rate in the irrigation system to ensure adequate water supply to the crops.

l HVAC systems: Horizontal Multistage Centrifugal Pumps are used in heating, ventilation, and air conditioning (HVAC) systems to circulate water or other fluids to maintain the desired temperature and humidity levels.

l Industrial processes: Horizontal Multistage Centrifugal Pumps are used in various industrial processes, such as chemical production, oil and gas refining, and power generation. They are used to transfer fluids, such as chemicals, crude oil, and water, through the production process.

l Pressure boosting: Horizontal Multistage Centrifugal Pumps are used to increase the pressure in water supply and distribution systems and other fluid handling systems to ensure adequate flow and pressure.

l Firefighting systems: Horizontal Multistage Centrifugal Pumps are used in firefighting systems to pump water from a source, such as a fire hydrant or a reservoir, to the fire hose or sprinkler system. They also increase the pressure and flow rate in the firefighting system to ensure effective fire suppression.

l Oil and gas production: Horizontal Multistage Centrifugal Pumps transfer fluids, such as crude oil, natural gas, and produced water, through the production process. They also increase the pressure and flow rate in the production system to ensure efficient production.

l Refining and processing: Horizontal Multistage Centrifugal Pumps are used in oil and gas refining and processing to transfer fluids through the refining process, such as crude oil, gasoline, and diesel fuel. They are also used to increase the pressure and flow rate in the refining process to ensure efficient processing.

l Pipeline transfer: Horizontal Multistage Centrifugal Pumps transfer fluids, such as crude oil and natural gas, through pipelines from the production site to the refining and processing facilities or distribution network.

l Offshore applications: Horizontal Multistage Centrifugal Pumps are used in offshore oil and gas production platforms to transfer fluids, such as crude oil and produced water, from the platform to the storage tanks or transportation vessels.

In summary, Horizontal Multistage Centrifugal Pumps are used in various applications and industries to transfer fluids, increase pressure and flow rates, and maintain desired temperature and humidity levels. Their versatility and efficiency make them popular for various fluid-handling applications.

How Horizontal Multistage Centrifugal Pumps Work

Horizontal Multistage Centrifugal Pumps use multiple impellers to increase a fluid's pressure and flow rate. The impellers are mounted on a single shaft and rotate at high speed, creating a centrifugal force that accelerates the fluid and pushes it toward the outer edge of the impeller.

As the fluid moves through each impeller stage, it gains energy and velocity, which increases the pressure and flow rate. The diffuser, a stationary component surrounding each impeller, helps convert the fluid's kinetic energy into pressure energy as it exits the impeller. The diffuser also directs the liquid to the next impeller stage in the pump.

Using multiple impellers and diffusers, a Horizontal Multistage Centrifugal Pump can achieve higher pressure and flow rates than a single-stage pump, making it suitable for various applications.

Components of the Pump

The primary components of a Horizontal Multistage Centrifugal Pump include:

- Impeller: The rotating component that accelerates the fluid

- Diffuser: A stationary component that channels the fluid from one impeller stage to the next

- Shaft: The central axis that connects all the impellers

- Casing: The outer enclosure that houses the impellers, diffusers, and other internal components

At YANESS, we use high-quality materials and components in our pumps to ensure reliability and efficiency.

Pressure and Flow Rate

The pressure generated by a Horizontal Multistage Centrifugal Pump depends on the number of impeller stages, the impeller design, and the rotation speed. The flow rate is determined by the pump's capacity and its efficiency.

In summary, Horizontal Multistage Centrifugal Pumps use multiple impellers and diffusers to increase a fluid's pressure and flow rate. The number of impeller stages, design, and the pump's rotation speed determine the force generated. In contrast, the pump's capacity and efficiency define the flow rate.

Types of Horizontal Multistage Centrifugal Pumps

Based on Impeller Design

There are two primary impeller designs:

- Closed impellers: More efficient and suitable for clean fluids

- Semi-open impellers: Suitable for handling fluids with suspended particles

At YANESS, we offer closed and semi-open impeller designs to meet the needs of different applications.

Based on the Shaft Seal

There are three main types of shaft seals:

- Mechanical seals: Provide a leak-free seal with minimal friction

- Gland packing: A traditional method that uses compression packing to seal the pump

- Magnetic drive: A contact-free seal that relies on magnetic forces to transfer torque

At YANESS, we offer pumps with different types of shaft seals to meet the needs of various industries and applications.

Based on Material

Pump materials can vary depending on the application and fluid being pumped:

- Cast iron: Suitable for general applications

- Stainless steel: Resistant to corrosion and suitable for aggressive fluids

- Bronze: Ideal for marine applications and corrosive environments

At YANESS, we offer pumps made of different materials to meet the needs of various industries and applications.

Advantages of Horizontal Multistage Centrifugal Pumps

High Efficiency

Horizontal Multistage Centrifugal Pumps are highly efficient due to their multistage design and ability to generate high pressure and flow rates. This can result in lower energy consumption and operating costs.

Compact Design

These pumps have a compact design, allowing for easy installation and reduced space requirements. This makes them suitable for applications where space is limited.

Scalability and Flexibility

Horizontal Multistage Centrifugal Pumps are scalable and flexible, allowing for easy customization and adaptability to various applications and system requirements. At YANESS, we offer pumps with different numbers of impeller stages and capacities to meet the needs of other applications.

Low Maintenance

With fewer moving parts and a robust design, these pumps require minimal maintenance, reducing operational costs and downtime. At YANESS, we offer pumps designed for easy maintenance and inspection.

Selecting the Right Horizontal Multistage Centrifugal Pump

Factors to Consider

When choosing a Horizontal Multistage Centrifugal Pump, consider factors such as:

l Application requirements

l Fluid properties

l Pressure and flow rate requirements

l Material compatibility

l Available space

At YANESS, our experienced engineers can help you select the right pump for your needs.

Sizing and Pump Performance

Proper sizing and selection of a pump ensure optimal performance, efficiency, and longevity. Consult with a pump specialist or use sizing software to determine the best pump for your application. At YANESS, we offer pump sizing and selection services to ensure our customers receive the best pump.

Installation and Maintenance

Proper installation and maintenance are crucial for maximizing the performance and longevity of a Horizontal Multistage Centrifugal Pump. Follow the manufacturer's instructions for installation, operation, and maintenance. At YANESS, we provide comprehensive installation and maintenance instructions for all our pumps.

Conclusion

In summary, Horizontal Multistage Centrifugal Pumps are versatile and efficient pumps that can handle a wide range of fluids and applications. With their multistage design, they can generate high pressure and flow rates, making them ideal for various industries and applications. At YANESS, we offer a range of high-quality Horizontal Multistage Centrifugal Pumps designed for reliability, efficiency, and ease of use. Our experienced engineers can help you select, size, install, and maintain the right pump.

FAQs

Q: What is the primary purpose of a Horizontal Multistage Centrifugal Pump?

A: The primary purpose of these pumps is to efficiently transfer fluids by converting kinetic energy into pressure energy, making them suitable for a wide range of applications.

Q: How does a Horizontal Multistage Centrifugal Pump differ from a single-stage pump?

A: A single-stage pump has only one impeller, while a multistage pump has multiple impellers working in tandem to generate high pressure and flow rates.

Q: What factors should I consider when selecting a Horizontal Multistage Centrifugal Pump?

A: Consider factors such as application requirements, fluid properties, pressure and flow rate requirements, material compatibility, and available space.

Q: Can Horizontal Multistage Centrifugal Pumps handle abrasive or corrosive fluids?

A: Depending on the material and impeller design, these pumps may be suitable for handling abrasive or corrosive fluids. Consult a pump specialist to determine the best pump for your application.

Q: How can I ensure the longevity and efficiency of my Horizontal Multistage Centrifugal Pump?

A: Regular maintenance, proper installation, and promptly addressing any issues can help ensure your pump's longevity and efficiency.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province