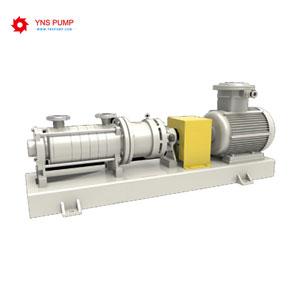

Chemical Process Pump with Magnetic Drive

- Product Item : 07102601

- Category: Magnetic Drive Pump

- Material: 304, 316, 904L, duplex steel, titanium alloy, hastelloy

- Flow: 1.5-1400m³/h

- Head: 10-168m

- Power: 1.5-900kW

CA/E series Chemical Process Pump with Magnetic Drive is a high-tech product with international leading level introduced by German technology. Applying the principle of magnetism, the contactless transmission of torque is realized, the shaft seal device (filler seal or mechanical seal) of the traditional centrifugal pump is eliminated, and the dynamic seal is replaced by a static seal to achieve a completely sealed and leak-free new chemical process pump. Industrial environmental protection equipment that eliminates industrial leakage, prevents pollution, and ensures environmental purification is listed in green chemical equipment.

Pump material

304, 316, 904L, duplex steel, titanium alloy, Hastelloy, etc.

Manufacturing standards

CA/E series Chemical Process Pump with Magnetic Drive are manufactured to API685-2000 standard production, CA foot support, CE center support.

Product features

● The structure and performance of the magnetic transmission device are superior: the magnetic pump produced by YANESS adopts a unique magnetic drive device with dense, magnetic and magnetic magnetic coupling. This coupling structure is commonly used in similar products in the world advanced countries. Compared with the driving device with the decentralized, gap-type and phase-absorbing magnetic circuit coupling, it has the advantages of small volume, large torque, small eddy current, high transmission efficiency and good reliability (in the magnetic circuit structure, the possibility of slippage is eliminated). Completely overcome their shortcomings and lead the world.● The efficiency of the pump is generally higher than 5-10% of the similar products in the world's advanced countries: the magnetic drive device adopts the patented technology to carry out serialized optimization design, and combines the unique process and manufacturing to affect the efficiency of the magnetic pump. The various losses are reduced to a minimum, so that the efficiency of the centrifugal magnetic pump is substantially the same as the efficiency of the shaft seal.

● Low natural wear rate and long maintenance-free period: It has a unique magnetic pump axial force balance system, which makes the axial force almost zero, which can make the thrust bearing end face and the sliding bearing end face only in the long-term operation of the pump. It produces very slight mechanical friction, so the natural wear rate is low, the failure rate is low, and the maintenance-free cycle is long.

● The vibration and noise of the pump are lower than those of similar foreign products.

Use of the product

The Chemical Process Pump can be widely used in the production process of chemical, petrochemical, pharmaceutical, printing and dyeing, etc. to transport clean liquid without particles and specific gravity of not more than 1.84, especially suitable for flammable, explosive, toxic, harmful, corrosive and valuable liquid. Delivery of media. The non-leakage magnetic pump is an ideal green chemical equipment, which will bring high economic benefits to the industries such as chemical industry, petrochemical, pharmaceutical and printing and dyeing industries, such as increasing production and saving, eliminating pollution, protecting the environment, safe production and labor protection. Social benefits. The CA/E series magnetically driven centrifugal chemical process pump is a standard leak-free centrifugal pump that can replace centrifugal pumps and shielded electric pumps with shaft seals.

Performance range:

Design pressure: CE is 2.5Mpa, CE is 5.0Mpa; flow rate: 5.5-2000m3/h; head: 16-168m; power: 1.5-900kw;

Applicable temperature

CE: -30 ~ 200 ° C; CE: -30 ~ 350 ° C;

Optional accessories

Temperature monitoring device, anti-air operation device, leakage monitoring device;

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province