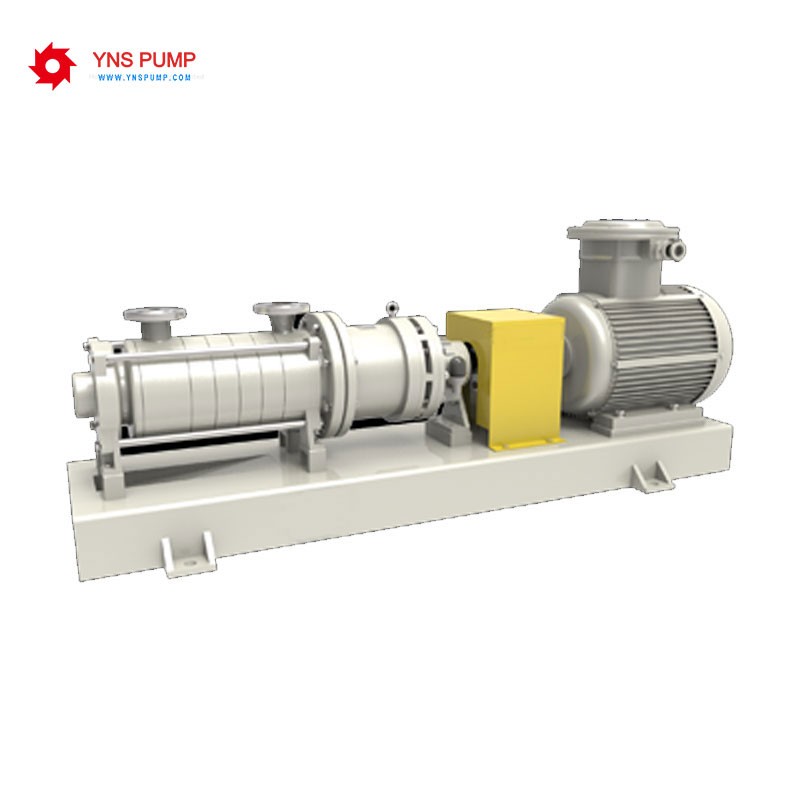

Multistage Centrifugal Pumps with Magnet Drive

- Product Item : 071024

- Category: Magnetic Drive Pump

- Material: SS304L, SS316L

- Flow: 2-20m³/h

- Head: 20-400m

- Power: 3-160

CD Multistage Centrifugal Pumps with Magnet Drive is designed by our company to solve the problem of small flow and high lift fluid transport. Its structure, hydraulic and magnetic circuit design adopts advanced and novel technology, and successfully applies magnetic drive technology to multi-stage magnetic centrifugal pump, which solves the high-power, large-gap magnetic circuit design and the axial force balance of multi-stage pump under high working pressure. And static sealing problems. At the same time, the combination of magnetic drive coupling and bearing failure monitoring device ensures the long-term safe and reliable operation of the pump.

● CD Multistage Centrifugal Pumps with Magnet Drive is YANESS's self-developed horizontal radial split according to HG/T 2730-2012.API685-2000. The outer casing is cylindrical structure and the inner shell issegmental structure. Sealed, leak-free, non-polluting new typeof industrial pump with small flow, high lift and small volume;

● The material of the flow body such as pump body, inner rotor, pump cover, impeller, isolation sleeve and pump shaft can be precision casted by 304, 316, 316L, 904, TA2, HC276 and other materials;● The pump body and pump cover adopt CFD computer fluid dynamics design hydraulic components for module design and precision casting. They should be able to withstand the erosion of high-speed and high-pressure liquid, and can withstand the impact of transient thermal shock. It has high anti-cavitation ability and smooth flow path. Good interchangeability to ensure the corrosion resistance and pressure resistance of the pump;

● The impeller adopts CFD computer fluid dynamics design hydraulic components for module design and precision casting to ensure reliable torque transmission. Its closed structure, flow channel optimization design, high efficiency, low NPSHR value, good interchangeability, guarantee the pump Flow and head stability;

● The isolation sleeve is made of 316L, TA2, HC276 and other materials and low vortex spacer. The isolation sleeve is in a sinusoidal alternating magnetic field, and the eddy current is induced and converted into heat in the section perpendicular to the magnetic line. The high-resistivity, high-strength HC276 material can be used to make the isolation sleeve, which is very effective in reducing the eddy current, eliminating all excess heat and reducing energy consumption; having high fracture pressure resistance, high safety factor, and pumping chamber It is completely isolated from the outside world, so that the pump chamber is completely sealed, and no leakage is achieved during the transportation process.

● The moving ring, bushing and sliding bearing adopt high-wearing and temperature-resistant crystalline silicon carbide, tungsten carbide and other materials, which have high strength, wear resistance, good arbitrariness and corrosion resistance, effectively ensuring the service life of the pump. ;

● The magnetic block is made of samarium cobalt 2:17, its magnetic energy product is 28 mega-Gauss, and the temperature tolerance is 350 °C, which can greatly avoid demagnetization, so that the theoretical service life of magnetic materials is up to 20 years. ;

● The pump axial force self-balancing structure utilizes the principle of fluid hydraulics to automatically balance the axial force through the fluid pressure difference. The thrust plate of the rolling bearing only receives the unbalanced axial force at the moment of starting and stopping, and can be operated at the working point. The axial force is almost zero, which greatly improves the stability of the whole machine operation;

● The magnetic pump adopts double sliding bearing structure, which makes the operation more stable, makes the medium flow smoothly, and the lubrication effect of the sliding bearing is better; the elastic gasket structure in the bushing and the sliding bearing prolongs the service life of the bearing and reduces the vibration of the pump. At the same time, the sliding bearing cracking due to high temperature conditions is avoided;

● No leakage, all sealing points are closed static sealing, driven by magnetic coupling, no need for nitrogen seal, safe, economical and efficient, to solve the medium leakage;

● Transmission parts Rolling bearings use SKF or NSK grease to lubricate maintenance-free bearings.

● The internal circulation cooling and lubrication method is more suitable for conveying various fluid media, including easily vaporized media;

● Select the foot support (basic type) and the center support (high temperature type) according to the medium temperature.

Application

Widely used in petroleum, chemical, acid, alkali, smelting, rare earth, pesticide, dye, medicine, paper, electroplating, electrolysis, pickling, radio, chemical foil, scientific research institutions, defense industry and other production processes Corrosive liquid, especially suitable for the transportation of flammable, explosive, volatile, toxic, high temperature, strong acid and alkali, organic and precious liquids.

Performance range

Design pressure: 1.6-6.4Mpa, flow rate: 2-20m3/h, head: 20-400m, power: 3-160kw;

Applicable temperature

-20 ~ 120 ° C, using new materials temperature resistance up to -20 ~ 400 ° C;

Optional accessories

Temperature monitoring device, anti-air operation device, leakage monitoring device;

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Mr.Zhang

Mobile:+86-13526505333

Tel:+86-0371-64032585

Whatsapp:+86 135 2650 5333

Email:[email protected]

Add:Gongyi City, Henan Province